Customized product solutions

RAPA Automotive develops customized individual solutions and components that meet your individual needs. Whether small modifications or a completely new development - our experienced experts will offer you the best solutions. We accompany you through the entire development process, from concept development and prototypes to technical design during series production. Production planning and the development of operating resources are also part of our range of services.

At RAPA Automotive, we attach great importance to customer satisfaction. That is why we offer our customers from the premium segment everything from a single source - from pre-development and test series through to the finished product in series production. RAPA Automotive is therefore your external development center, offering you all the advantages of a large company without having to forego customer service and advice. We work very closely with our customers to find the best solution together.

In the first phase, we develop concepts and simulations, calculate various options and conduct basic research. In the second phase, we carry out tests on the life cycle, manufacturability and production processes. After each of these phases, we carefully check whether the desired product performance can be achieved. In this way, customer requirements can be implemented flexibly.

ManufacturingTest laboratoryPrototype constructionsimulationCertificates

In-house production

An essential core area of our activities is production, because RAPA not only develops high-tech vehicle components, but also produces, manufactures and assembles them - and even designs the production systems for them. From manual workstations to fully automated production lines. Based on its experience in production, RAPA creates modular concepts for assembly and testing, which are developed in cooperation with the suppliers. The specially created framework is used to breathe life into the systems with countless industrial robots and NC systems, and every step is checked in daily operation.

Our conviction:

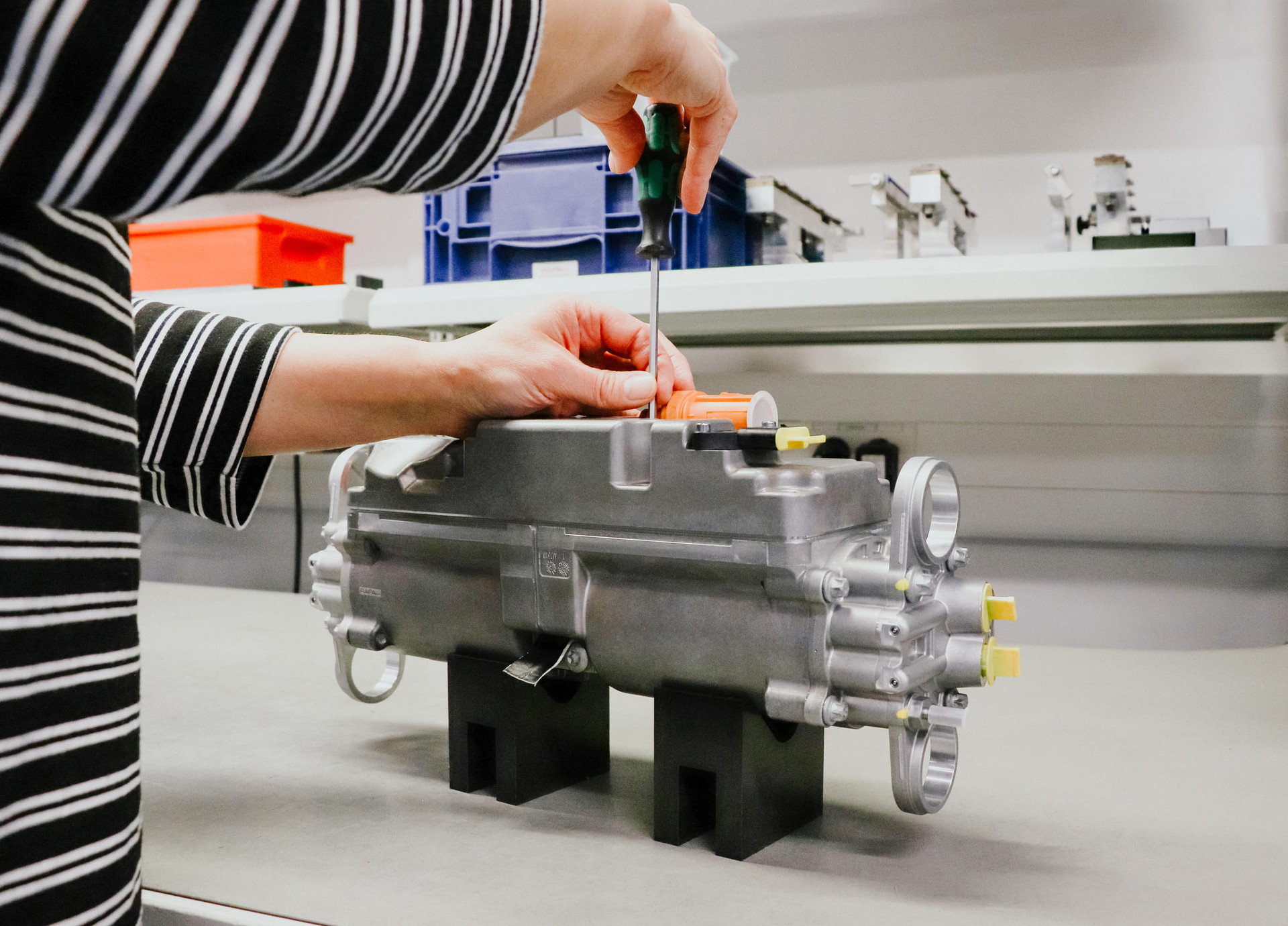

Cooperation between man & machine

Well-trained skilled workers work in our production facilities, ensuring that our parts and system components are manufactured and delivered. Anyone walking through our factories can see every day how components are assembled with skilled craftsmanship and a steady hand. Only this genuine manual work, in combination with fully automated production and robots, ultimately leads to RAPA's globally sought-after product quality and high productivity.

Facts, figures and data

Several thousand components are produced every day on 11,000m2 of production space in Selb | Germany and over 3,400m2 each in Auburn | USA and Jintan | China. It goes without saying that all our sites are certified in accordance with the strict automotive standards. As a developer and supplier, we bear responsibility for the success of our customers. With our integrated quality management system, we meet the growing demands of the industry and offer our customers the highest possible performance and safety.

Dr. Gregor Stengel

Head of Factory Automation

We believe that those who manufacture in-house think differently when it comes to design and have a different view of the optimization potential of components, parts and systems. Furthermore, in-house production makes it possible to significantly shorten development times, especially if the process technology is developed in parallel.

Test laboratory

We guarantee the highest quality and performance for RAPA products and fulfill these within the framework conditions specified by our customers.

Our products are developed and tested with regard to the following aspects:

- Functional safety

- Service life

- Size

- Weight

- Torque

- Flow rate

- Pressure drop

- Noise development

- Heat development

- Vibration

- Energy consumption

Only in this way can our components and systems reliably fulfill their function in the overall vehicle system and demonstrate decisive competitive advantages.

Locations & employees

Around 35 employees work in the test laboratory at RAPA Automotive worldwide. The engineers, physicists, technicians and physics laboratory technicians employed there specialize in everything from design and automation to programming.

A total of 3,000m2 of laboratory and validation space is available at our locations in Germany, the USA and China. The central laboratory in Germany plays a special role in the global networking and standardization of test procedures and processes.

Tasks & activities

Around 90 percent of all necessary testing and validation procedures are carried out internally at RAPA Automotive in order to meet the special and complex requirements of the automotive industry and to be able to react flexibly to customer requests. For tests outside RAPA Automotive, we work together with long-standing partner laboratories that know our products and test programs in detail.

The RAPA test laboratory focuses in particular on complex tests with combined loads in terms of function, service life, temperature and climate. These represent the greatest challenge in product development and are developed and supervised directly in-house by our experts.

In addition to these tests, the laboratory and development team is available for test drives and trials on the vehicle at the customer's premises and can provide quick and uncomplicated support, understand effects at system level and finally carry out the comparison with internal tests.

Laboratory equipment

The locations are equipped according to the product groups localized there

| Selb | Germany | Auburn | USA | Jintan | China |

|---|---|---|

|

|

|

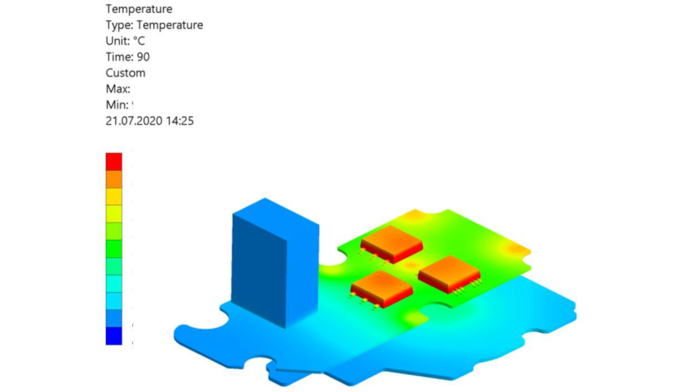

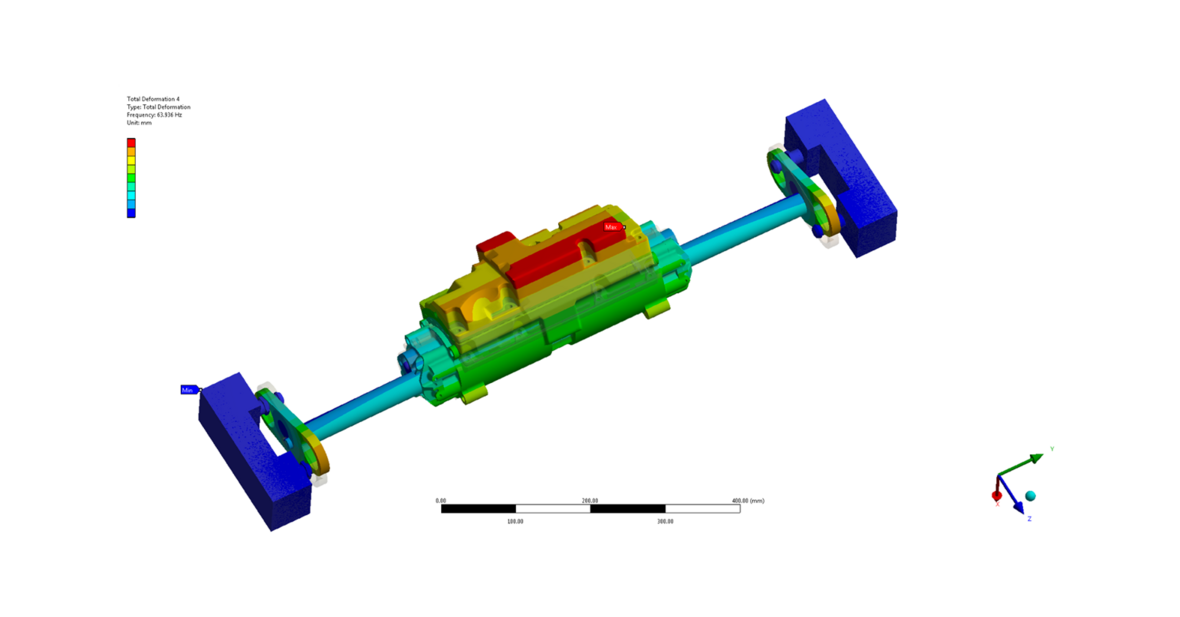

In addition to drift and trend analyses, the data obtained using modern and highly automated measuring and testing methods is also incorporated into computer simulation models.

Johannes Geiger

Head of testing laboratory department

In order to cover the global scope of validation in the best possible way, we are represented at all locations with one test laboratory each. We develop standardized test methods together through constant exchange. This enables us to use our capacities efficiently, make the best possible use of existing equipment and benefit jointly from expansions.

Prototype construction

Prototype construction at RAPA Automotive combines several tasks:

- Prototype planning

- Prototype construction

- Process laboratory, incl. small series production

By building prototypes in-house, the development process can be supported with the very flexible provision of prototypes. Changes and re-evaluations can also be implemented in a short time thanks to internal availability, the associated short communication channels and complete transparency.

The devices and systems required for prototype production are designed by the in-house equipment design department in close cooperation between process engineering, development and prototype construction.

The often quoted statement by Horst Pausch (Chairman of the RAPA Supervisory Board) is still our current guiding principle today and illustrates the relevance of our sample and prototype construction:

“Our samples are the ticket to our customers.”

Tasks & activities

Prototype disposition

Our complex prototypes are used in acquisition on the one hand and tested and optimized together with customers on the other.

The scheduling department is responsible for coordinating and bringing together all the necessary drawings, individual parts, devices and equipment.

Prototyping

Initial samples, A, B and C samples as well as all special and quality parts are supported, managed and manufactured from procurement to delivery. The production of complex samples for simulation comparisons also takes place here.

The spectrum ranges from the realization of initial ideas from pre-development to the production of larger sample quantities for development projects, thus providing the basis for series production.

Pre-series production & process laboratory

Small series are produced under conditions close to production and sometimes with individual parts that fall out of the tool, and process data is recorded in this context.

The knowledge gained in the prototype phase enables the start of series production to be accelerated.

Rocco Kemnitz

Head of Pre-Development Department

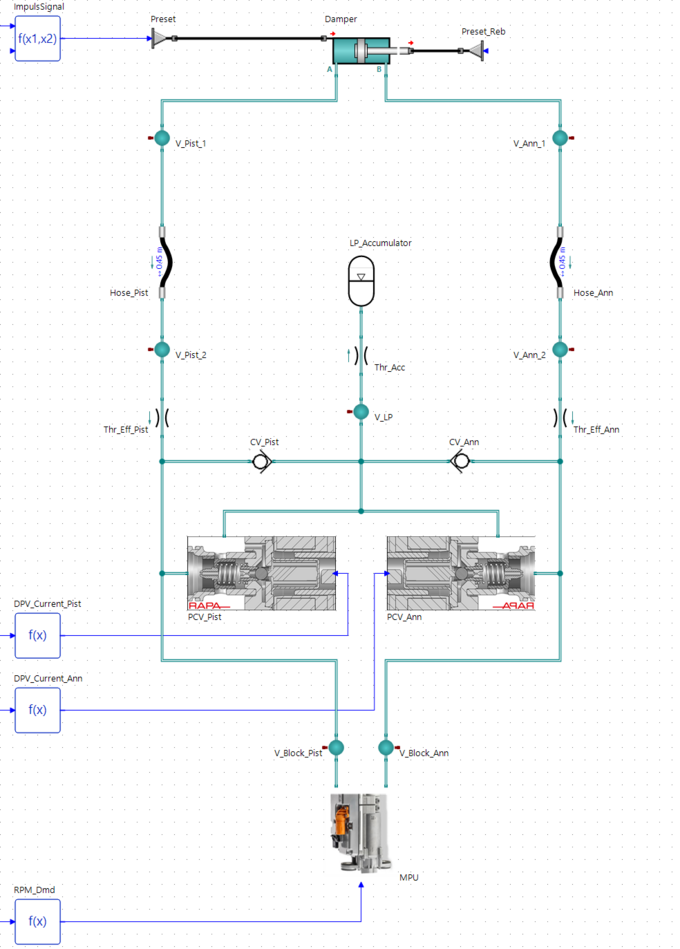

Thanks to our in-house simulation expertise, we are much more flexible and can therefore optimally support the internal development process. In addition, cooperation with the customer also benefits from internal availability. For example, we have more opportunities to optimize the interfaces between our products and the customer system.

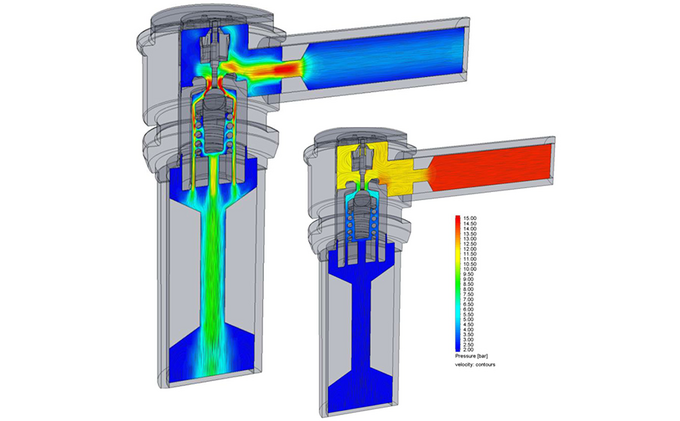

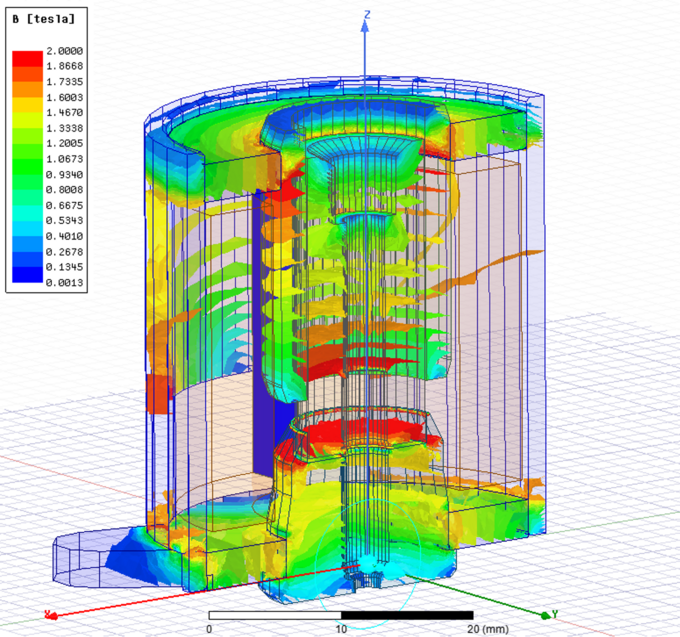

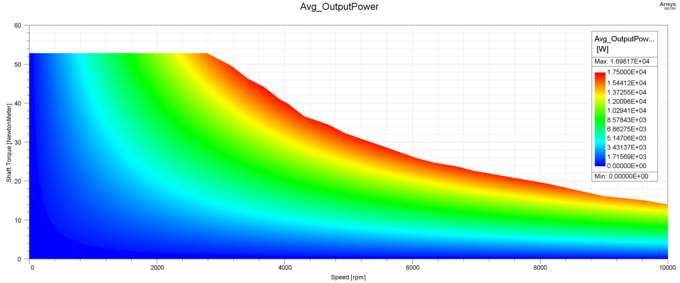

Simulation

Support of the internal development process at RAPA Automotive

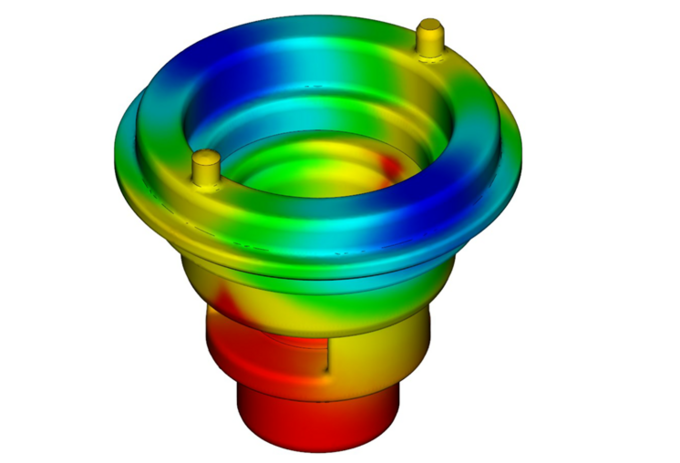

- Simulative optimization on virtual prototypes before implementation in physical samples

- Use of various simulation techniques to optimize certain product properties: Functional optimization, weight reduction, material savings, vibration resistance, noise reduction

- Creation of digital product twins for the simulation-supported development of functions and assembly processes along the entire product development process

Support for our customers

- Optimized coordination between customer system and RAPA product through early simulation

- Early consideration of interactions in the customer system and possible reactions

Certificates

RAPA attaches great importance to the quality of its products, environmentally friendly business practices and the sustainable use of resources. We work together to ensure reliable environmental protection that goes beyond laws and regulations and thus make our contribution to the next generation and our region.

You can find the certificates in the download area.

IATF 16949:2016

Automotive quality management

Certification in accordance with IATF 16949:2016, the standard for QM systems in the automotive industry, is a mandatory requirement for inclusion in the supplier base of automotive manufacturers and their suppliers. By achieving certification, RAPA sees an increase in performance and responsibility to implement customer requirements in a quality-oriented and targeted manner. Benchmarking and the optimization of our processes are key qualifications for further milestones in our success.

Certified: since 2006 | Selb site

Certified: since 2016 | Auburn/USA site

ISO 9001

Quality management

The ISO 9001 quality management standard is the most widely used standard in quality management both nationally and internationally. As a company, we are committed to implementing and maintaining a documented quality management system (QM system) that is firmly anchored in our organization. The ISO 9001 certification is a clear sign of our commitment to top quality and continuous improvement.

Certified: since 2021 | Selb site

EMAS validation

Environmental management

RAPA is not only certified in accordance with the ISO 14001 environmental standard, but is also registered in the European EMAS register. This regulation requires continuous improvement in environmental performance, which is recorded in the annually updated environmental statement.

Validated: since 2016 | Selb site

ISO 14001

Environmental management

The international standard ISO 14001 stands for the implementation of and compliance with an environmental management system. RAPA has set itself the goal of implementing environmental protection above and beyond its binding obligations.

Certified: since 2007 | Selb site

Certified: since 2017 | Auburn/USA site