E-ACTIVE-BODY-CONTROL

In the new Mercedes-Benz GLE, Mercedes-Benz is introducing E-ACTIVE BODY CONTROL, a chassis system developed from scratch. It offers a high level of ride comfort, driving dynamics and off-road characteristics.

Mercedes-Benz

"The greatest pride of our developers is the engine-pump unit integrated into the E-ACTIVE BODY CONTROL chassis. A masterpiece of German engineering that confirms our status as a premium product supplier to the automotive industry.

Oliver Henkelmann-Mattheus, General Manager RAPA Automotive

The development project

Since the company was founded over 100 years ago, RAPA Automotive has been known for its continuous development and innovative product solutions. Its strategic vision in high-tech niches and its reputation as a flexible and innovative development service provider have made the family-owned company from Upper Franconia a recognized technology partner and hidden champion in the automotive, medical and industrial sectors.

RAPA Automotive has been part of the automotive supplier world since the 1980s - and has been closely associated with Mercedes-Benz ever since. This important partnership for RAPA Automotive has also been established for over 20 years in the field of active chassis control systems; since 2005, the so-called ABC© (Active Body Control) has been the non-plus-ultra in the Group's luxury class vehicles.

This is based on a highly complex hydraulic system that can only be used to a limited extent for future innovations, not least because of its dependence on the combustion engine. A completely new solution was needed that would meet the main requirements, such as a pressure-tight, compact four-quadrant unit, high overall efficiency, dynamic volume flow control, 48 V operating voltage, integrated electronics and optimum NVH behavior.

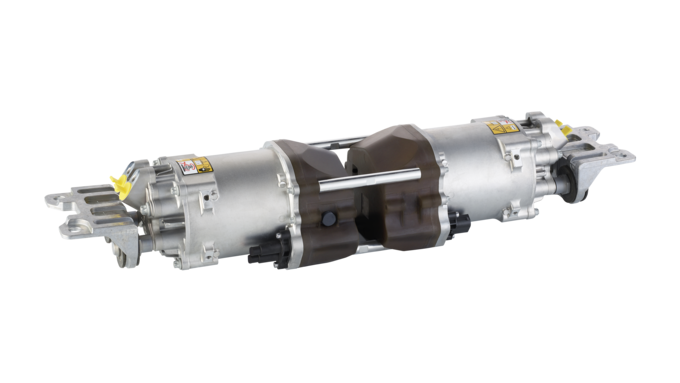

After six years of development, the motor-pump unit (MPE) with integrated control electronics for the E-ACTIVE-BODY-CONTROL of the new Mercedes-Benz SUV GLE was created - an important milestone in the history of RAPA Automotive.

Facts, figures and data | |

|---|---|

| Type | Electro-hydraulic motor-pump unit |

| Flow direction | Reversible depending on the direction of rotation of the electric motor |

| Operating modes | Pump operation and generator operation in both directions of rotation |

| Power output | Max. 3.5 kW per motor |

| Operating pressure difference | Max. 120 bar |

| Volume flow | Max. 27 l/min |

| Protection class | IP6K9K |

| Installation position | Any (preferably in axle alignment, parallel to the axle carrier) |

Special Award Innovation

At the 11th Mercedes-Benz awards ceremony on February 20, 2019, RAPA Automotive received the Supplier Award Innovation for the development of the engine-pump unit, whose sophisticated and intelligent control generates pressures individually in each shock absorber. To be experienced in the new Mercedes-Benz GLE as E-ACTIVE-BODY-CONTROL suspension. The aluminium trophy, weighing almost two kilos, was presented to Dr. Roman Pausch by Ola Källenius, Member of the Board of Management of Mercedes-Benz for Group Research and Mercedes-Benz.

Dr. Roman Pausch, CEO RAPA Group summarizes:

'A success that makes us proud and spurs us on to pursue further customer-specific innovations with the same commitment. But without the open and cooperative partnership with our colleagues at Mercedes-Benz, the development of this world first would not have been possible.

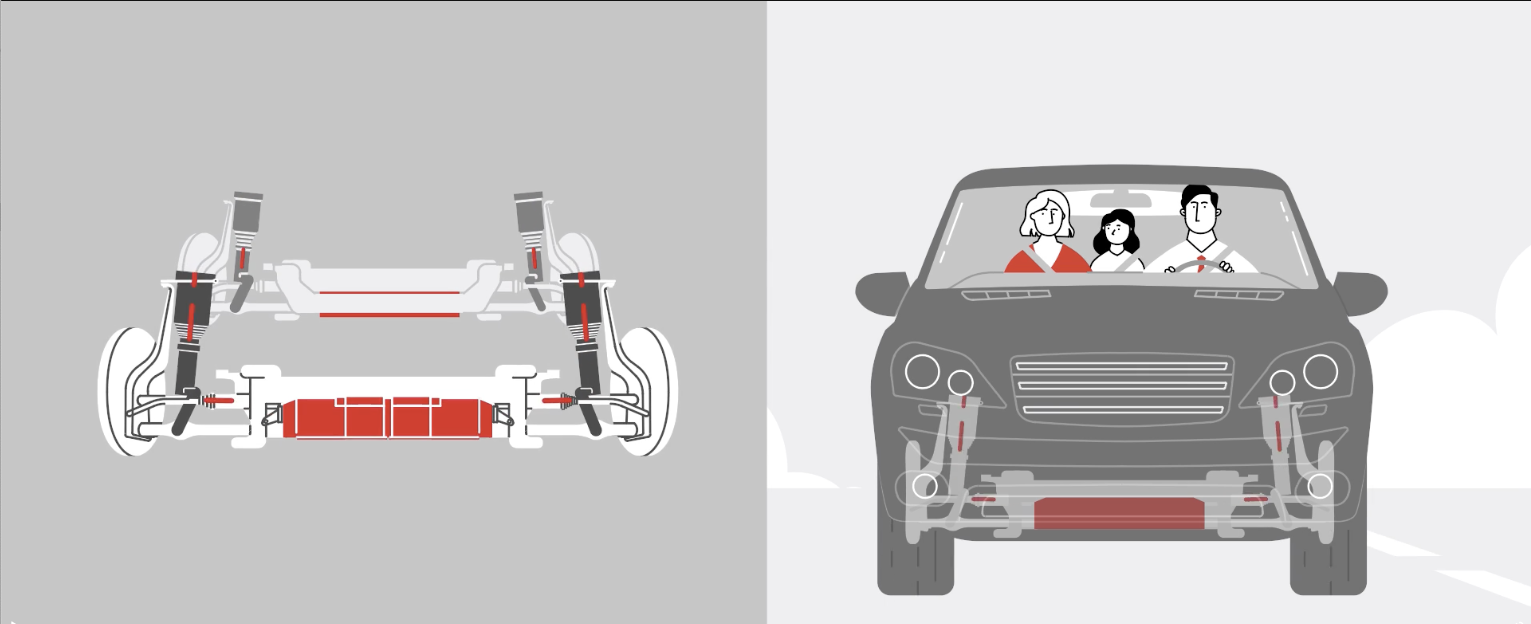

E-ACTIVE-BODY-CONTROL is a further development of the established ABC system. The road surface is recorded with the aid of a stereo camera and a corresponding control algorithm is created, which allows the passenger cell to be stabilized and leveled in any driving situation. Four corner models now act as actuators, consisting of an MPE and an active suspension strut in which the shock absorber is used as an actuator. Roll and pitching moments are compensated. In addition, the ride height can be changed, for example lowered when driving on the highway or raised off-road.

The MPE of the E-ACTIVE-BODY-CONTROL system is the product of RAPA Automotive, consisting of three main components:

- an internal gear hydraulic pump

- a permanently excited synchronous machine as an electric motor

- and the 48 V control unit including software from Silver Atena.

An internal gear machine was favored as the displacement principle.

In particular, a four-quadrant design with leakage compensation is used. Leakage compensation is implemented radially via pressure-activated and self-sealed split fillers and axially via pressure plates, which are also sealed on the back and slide on the gear set. This design enables the machine to achieve very high volumetric efficiencies. Particularly in alternating operation around the point of origin of the machine's characteristic map, this produces very good response behavior. The volumetric efficiency of the machine is almost 100 % in this range. The high efficiency is necessary because active cooling should be avoided at all costs.

In addition to the four-quadrant capability and the very high volumetric efficiency, the selected displacement principle also offers a very compact design and very good possibilities for a high level of design integration between the displacer and electric motor.

Following intensive concept studies, a permanent-magnet synchronous machine was used for the electric machine.

The machine is designed as a wet rotor with a can. This posed a particular challenge in the development of the electric machine, as it was necessary to achieve high efficiency on the one hand and pressure resistance under all operating conditions up to at least 150 bar on the other. An eddy current-free can is a prerequisite for the most efficient operation of the machine, and RAPA Automotive has developed a thin-walled plastic part for this purpose. The wall thickness of the tube can be reduced to a few tenths of a millimeter in the magnetically relevant area of the machine. Contrary to this, the gap tube must be designed to be pressure-resistant despite the thin wall thickness, which is necessary for magnetic reasons. After numerous structural-mechanical simulations, RAPA Automotive has developed a geometry that is now patented, which is supported by the stator teeth under pressure and automatically stiffens.

The rotor has a classic spoke design. The permanent magnets integrated in the rotor laminated core are fixed in place by a plastic overmoulding directly integrated in the assembly flow. The overmoulding is also used for balancing the rotor, which is also arranged directly in the assembly line, via openings on the front. The stator consists of a stator star with the electrically connected individual tooth coils mounted on it and a back ring radially surrounding the star. Once the stator has been mounted in the housing, the assembly is encapsulated with a 2-component casting compound under vacuum.

The electronic unit integrated in the MPE was developed together with our partner Silver Atena.

The assembled, pre-assembled and pre-tested ECU is mechanically attached to the engine housing and electrically contacted in the assembly line at RAPA Automotive. The unit consists of a power board and a signal board. Both boards are constructed in the form of a stack with an assembly between the two boards to accommodate the DC link capacitors, the input choke and other components.

A rotor position sensor is used to detect the actual position of the rotor. Thanks to the design of the MPE, the rotor position sensor is positioned directly at the front in the base of the motor housing and is therefore located directly underneath the ECU. A Hall sensor is used as the sensor principle. The magnetic field required for the sensor, depending on the position of the rotor, is provided by a permanent magnet located at the electronics end of the shaft. The electrical interfaces to the vehicle consist of a 48 V connection for the power supply and the CAN connection for communication. The electronics provide numerous status variables of the MPE on the CAN connection. In addition to the typical variables such as speed, temperature, input voltage and current consumption, two pressure sensors integrated in the hydraulic machine also provide the actual sensed pressure at the two hydraulic connections of the MPE on the CAN bus. The power electronics are of great importance with regard to the overall performance of the E-ACTIVE-BODY-CONTROL, especially due to the high system safety requirements (ASIL level C).

The installation space requirements necessitate a highly integrated design of the motor-pump unit.

To this end, the hydraulic displacement machine and the electric machine are integrated into one another and connected via a common shaft. The concept of the continuous shaft enables a design with only three bearing positions, whereby the middle bearing is shared by both the internal gear machine and the electric machine. Another advantage of the chosen design with a wet-running rotor and a high level of integration between the hydraulic and electric machine is that only static seals are required for the atmosphere. This ensures robust sealing of the system over its service life and also completely prevents friction caused by the seal, and therefore losses, on the shaft. Depending on the installation space requirements in the vehicle, the MPE can be mounted very easily as a single MPE or as a complete MPE axle set using various brackets.

Testing the MPE presented RAPA Automotive's validation team with completely new challenges.

A complex functional test bench for the new product was designed, built and commissioned at an early stage. In addition, a wide variety of test benches had to be planned and set up for the complex test sequences, which took a total of eight months per test loop. As the device was also to be used in electric driving mode, the noise development of the MPE posed an extreme challenge for the suitability of the new product for series production. After intensive optimization loops consisting of simulative and experimental work in RAPA Automotive's noise measurement chamber and accompanying evaluations in the customer's vehicle, the necessary improvements were achieved. Numerous noise-relevant details in the hydraulic machine were optimized within the optimization loops. Minimizing the pressure pulsation played an important role in this.

Chairman of the Supervisory Board

Horst Pausch

For RAPA Automotive, the long-standing strong partnership with Mercedes-Benz is an important building block with which we underline our expertise as a partner to the automotive industry.

Chairwoman RAPA

Karin Wolf

The automotive industry and its suppliers are important customer groups for RAPA Automotive. In addition to close business relationships, RAPA Automotive is also involved in numerous research and development projects with them.

Chairman of the Executive Board RAPA

Dr. Roman Pausch

The central task is to maintain the high quality standards demanded by our customers and to adapt to new market requirements.