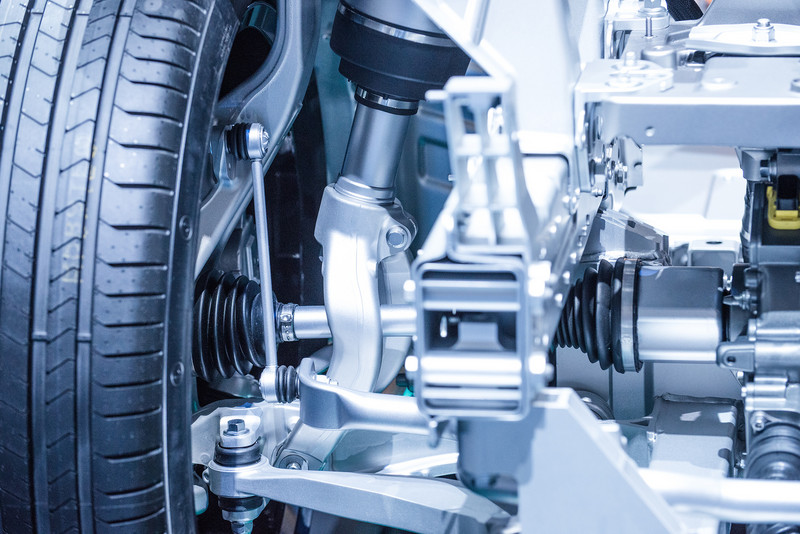

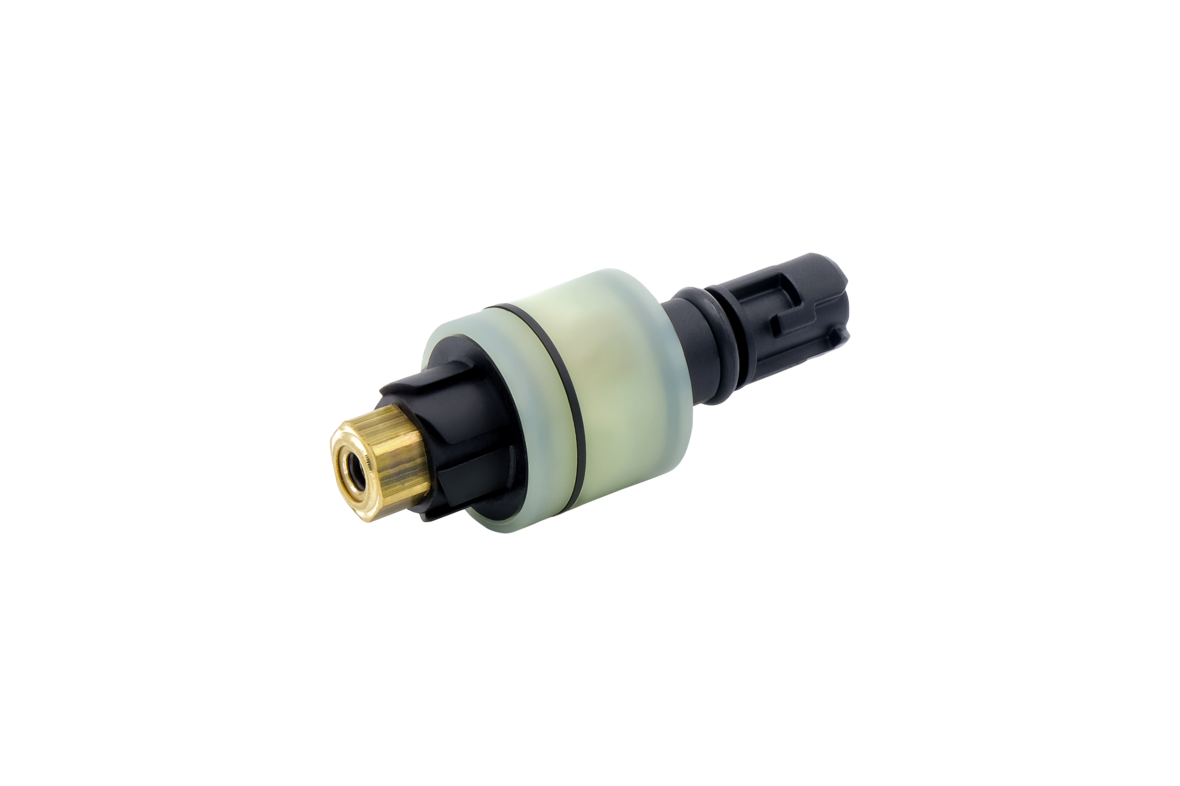

The mechanical residual pressure maintenance valves are installed at the interface between the suspension struts and air lines in the car and are used to maintain the minimum pressure in the air suspension strut.

How a residual pressure valve works

- Non-return valve that is open under pressure to establish a continuous connection with compressed air from the supply line into and out of the air spring

- Automatic closing of the valve if, for example, a defect occurs in the supply lines or in the air supply system in order to maintain residual pressure in the suspension strut

Reasons for the use of residual pressure maintenance valves

- Minimum pressure maintenance in the suspension strut to prevent damage to the elastomer rolling diaphragm and to maintain a safely drivable vehicle condition

- Pressure maintenance for problem-free storage of new, pre-filled air suspension struts until installation in the vehicle (storage possible for up to 7 months)

The flexible plastic solution offers advantages in terms of both weight and cost structure.

Technical Advantages of the RAPA Residual Pressure Valve

- Valve design depending on the positioning of the valve and the routing of the pneumatic hoses in the vehicle: stand-alone valve or top-mount integrated solution

- Best corrosion resistance due to the all-plastic solution

- Easy installation thanks to plug-in connection

- High tightness (both in the closed state from the air spring and to the environment) and switching capability over the entire operating temperature range (-40 °C to +100 °C, especially in the low temperature range down to -40 °C)